CARBON NANOTUBES

Tystar introduces a family of equipment for the fabrication of Carbon Nano Tubes (CNT) and Nano Wires. The CNT equipment can be used for both CNT research and production applications. The CNT equipment is available for both atmospheric and low pressure processes. All process steps from substrate loading to unloading are fully automated to ensure tight process control and reproducibility. CNT growth is typically carried out on catalyst coated wafers at temperatures of 750 - 800 °C, using C2H4and other hydrocarbons as feed gas. The reactor can process a batch of 50 substrates up to 6/150 mm diameter.

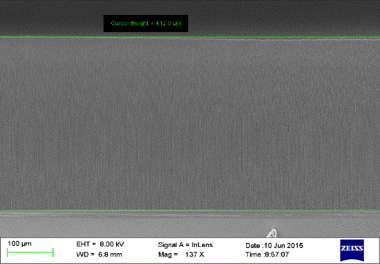

Courtesy of NUAA

Optional features available are:

- A sliding furnace for rapid sample heating

- A temperature controlled liquid precursor vaporizer

- All components for reduced pressure operation

- An electric field kit for directional growth

The diameter of CNT can vary from Single Walled CNT (SWCNT) to a micrometer depending on the recipes used. By careful choice of the substrate preparation and the process conditions, CNT can be produced in a variety of forms such as:

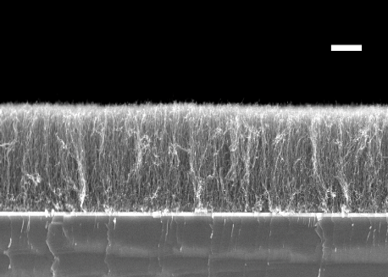

- Vertically Aligned CNT (the so-called VACNT or CNT forest) that can grow up to a few mm.

- Horizontally Aligned CNT (HACNT)

- Entangled (or cotton-like) CNT

Courtesy of NRC

CNT fiber tensile strength of 3.3 GPa has been achieved. CNT growth rates of up to 70 µm/min have been observed. Wafers are stacked vertically in a quartz holder; CNT growth is typically perpendicular to the substrate surface.

Areas of CNT application are many. Some of the examples are:

- Solar cells

- Batteries and super capacitors

- Displays and field emitters

- AFM tips

- Composite materials and fabrics

- Biomedical materials

- Conductive materials

- Air and water filters

For more details of CNT CVD, please contact 7050 Lampson Avenue Garden Grove, CA 92841 | Tel: (310) 781-9219 or write to support@tystar.com